Stricter Lead Regulations Starting in January 2025:

Who It Impacts and What Challenges It Imposes

As of January 1, 2025, Cal/OSHA has imposed stricter regulations in general industry and construction to protect workers from exposure to lead.

Background

The previous lead regulations was based on scientific data that was over 40 years old. As the understanding of the toxic effects of lead evolved, it became evident that the protective measures in the workplace were not adequate at reducing workers exposure to hazardous levels of lead. Cal/OSHA initiated the revisions to the lead standard 13 years ago after the health department contacted them with concerns. The development of the new standard was approved in February 2024, and went into effect on January 1, 2025.

Lead is a toxin that has no function in the body

Lead has no known benefits to the human body. It mimics calcium and fools the body into absorbing it into the blood and bones. Therefore, one leading indicator of a person's lead exposure is the concentration of lead in the blood. Once inside the body, it can cause anemia, hypertension, heart disease, reduced kidney function, gastrointenstinal issues, neurological hearing loss, reproductive issues, and more. The most common routes of exposures are from inhalation and ingestion. Although there are many sources of lead in our environment, occupational exposures can cause a worker to not only be exposed at work, but also bringing it home on shoes and clothes and inadvertently expose their families.

Purpose of the Revised Regulations

The goal of the new regulations is to keep workers' blood lead levels below 10 micrograms per deciliter (ug/dL). This will be achieved by reducing the airborne lead exposures, oral exposure, and require more frequent blood testing to monitor that the controls in the workplace are effective. The new regulations applies to both general industry and construction worksites. Changes to the Permissible Exposure Level are also published in Section 5155 - Airborne Contaminants, which include both inorganic lead and lead chromate.

Revisions in Title 8 Sections 1532.1 and 5198

The following are a few highlights of the most significant changes that employers have to comply with:

- The new PEL is reduced by 80%, from 50 micrograms per cubic meter (ug/m3) to 10 ug/m3). Airborne exposures to lead chromate is reduced from 20 ug/m3 to 10 ug/m3.

- The action level is reduced by 93%, from 30 ug/m3 to 2 ug/m3.

- Adding and defining terms, including trigger tasks, altering or disturbing, high efficiency particulate air (HEPA) filter, and presumed hazardous lead work (PHLW).

- Trigger tasks and PHLW must be performed with interim protections.

- Requiring certain hygiene practices at any lead exposure, not just exposures above the PEL.

- Removing the requirement for zinc protoporphyrin (ZPP) for routine blood lead testing as it is an insensitive biomarker for BLLs below 25 ug/dL. ZPP analysis is still required for workers with BLLs over 20 ug/dL.

- Reducing the duration certain work tasks can be performed.

- Special requirements for engineering controls in the manufacturing of lead acid batteries.

- Increased frequency of blood lead testing and developing a Response Plan when a worker's blood lead level is 10 ug/dL and higher (or if airborne lead exposures are above 500 ug/m3).

- Providing annual medical exams at a blood lead level of 20 ug/dL (old level was 40 ug/dL.

- Requiring that workers who get a blood lead level test are provided with certain information.

- Instituting medical removal at or above 30 ug/dL (old level was 50 ug/dL). Starting in January of 2026, the medical removal requirements will expand to also include when two consecutive BLLs are at or above 20 ug/dL (which used to be 40 ug/dL), or when the average of all BLLs for the past 6 months is at or above 20 ug/dL. The work restrictions for medical removal are expanded and includes not torch cutting scrap metal, or disturbing lead contaning materials, and an employee is not allowed to return to work until their BLL is no more than 15 ug/dL (old level was 40 ug/dL).

- Expanded training content.

We provide the following services:

- Interpretation of Cal/OSHA regulations

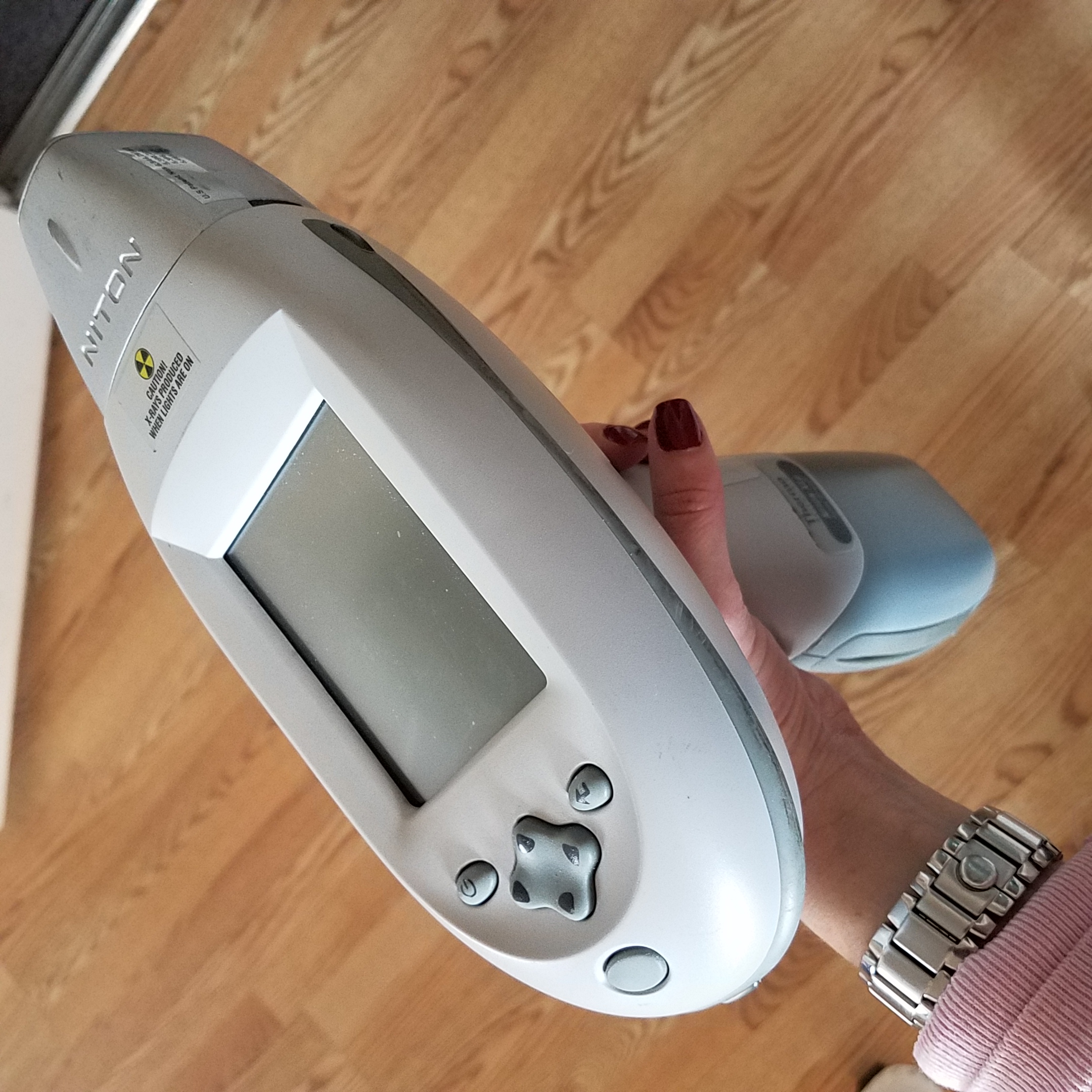

8 CCR 5198 and 1532.1 for lead - Lead air testing

- Identification of "regulated areas"

- Advice on feasible exposure controls

- Lead based paint testing

- Wipe sampling for settled lead dust

- Written lead exposure program

Call (562) 357-7783 today or use our Website Form to get expert guidance on navigating the Cal/OSHA lead regulations.

More Resources:

General Industry:

8 CCR Section 5198

Construction Industry:

8 CCR Section 1532.1

CA Department of Public Health:

Occupational Lead Poisioning Prevention Program